Sure! Here is a list of Frequently Asked Questions (FAQ) for sourcing vertical form fill and seal machines from SourcifyChina factory:

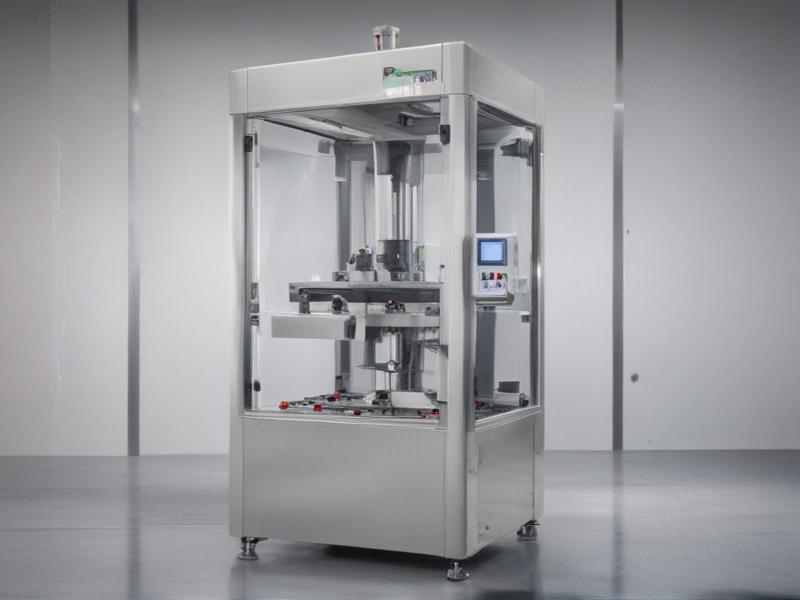

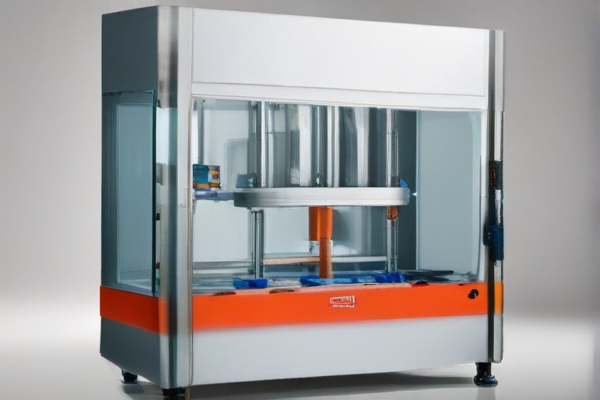

Q: What types of vertical form fill and seal (VFFS) machines does SourcifyChina factory offer?

A: SourcifyChina factory offers a range of VFFS machines suitable for various products, including granules, powders, liquids, and solids. They cater to different industries such as food, pharmaceuticals, and chemicals.

Q: Are the VFFS machines customizable?

A: Yes, SourcifyChina factory can customize the VFFS machines based on specific requirements, including size, packaging type, materials, and additional features.

Q: What is the lead time for an order?

A: The lead time varies depending on the complexity and scale of the order. Generally, standard models can be delivered within 4-6 weeks, while customized machines may take longer.

Q: How do I request a quote for VFFS machines?

A: To request a quote, you can visit SourcifyChina’s official website and fill out the inquiry form. Alternatively, you can contact their sales team via email or phone with your specific requirements.

Q: Does SourcifyChina factory provide after-sales support?

A: Yes, the factory offers comprehensive after-sales support, including installation assistance, operator training, maintenance services, and spare parts supply.

Q: What are the warranty terms for the VFFS machines?

A: SourcifyChina factory generally offers a one-year warranty on their VFFS machines, covering parts and labor. Extended warranty options may be available upon request.

Q: What are the payment terms for purchasing VFFS machines from SourcifyChina factory?

A: The payment terms typically include a deposit upon order confirmation and the balance before shipment. Detailed terms can be discussed directly with the sales team.

Q: Can I visit the factory to inspect the machines before purchasing?

A: Yes, potential buyers are welcome to visit the factory for a firsthand inspection of the machines and facilities. Appointments can be arranged through the sales team.

Q: Do they provide international shipping?

A: Yes, SourcifyChina factory can handle international shipping to various destinations. They work with reputable logistics partners to ensure timely and safe delivery of machines.

Q: How do I get technical support if I encounter issues with the machine?