Sure, here is a list of frequently asked questions (FAQ) with answers for sourcing a Vertical Form Fill & Seal (VFFS) machine from SourcifyChina factory:

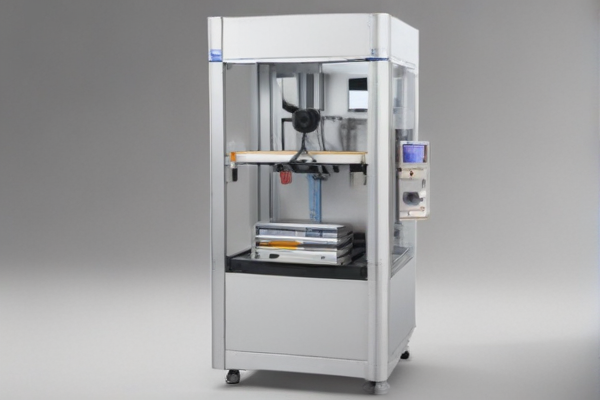

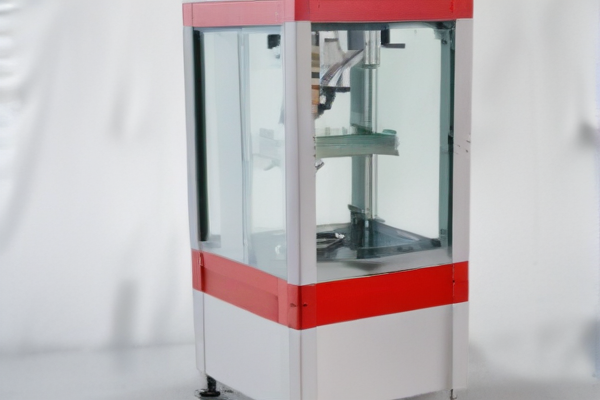

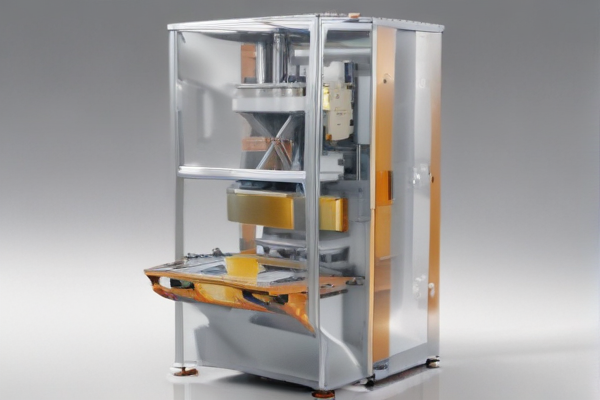

1. What are the key features of the Vertical Form Fill & Seal machine from SourcifyChina?

The VFFS machines from SourcifyChina typically feature advanced PLC control, high-speed sealing, user-friendly touch screens, and robust construction. They are designed for precision and efficiency in packaging various products.

2. What types of products can the VFFS machine package?

These machines can package a wide range of products including granules, powders, liquids, and solids. Common products include snacks, grains, spices, candies, liquids, and non-food items.

3. Can the machine be customized according to our specific needs?

Yes, SourcifyChina offers customization options for their machines. You can specify your particular requirements, such as bag size, sealing type, and special features, to ensure the machine meets your needs.

4. What is the lead time for delivery?

The lead time for delivery typically ranges from 4 to 8 weeks, depending on the level of customization and current factory workload. It’s advisable to confirm the exact lead time when placing your order.

5. What kind of technical support and warranty is provided?

SourcifyChina provides comprehensive technical support, including installation guidance, operator training, and troubleshooting. They also offer a standard one-year warranty on their VFFS machines and optional extended warranties.

6. What are the payment terms?

The common payment terms are T/T (Telegraphic Transfer), with a deposit required to commence production and the balance payable before shipment. Other payment terms can be discussed directly with SourcifyChina.

7. Are spare parts readily available?

Yes, SourcifyChina maintains a stock of common spare parts and can ship them quickly. They also offer an inventory plan for critical components to minimize downtime.

8. Is the machine easy to operate and maintain?

The VFFS machines from SourcifyChina are designed for ease of operation and maintenance. They come with an intuitive interface and comprehensive user manuals to aid operators.

9. What packaging materials are compatible with the VFFS machine?

The machine can work with a variety of packaging materials including laminated films, PE, and PP. It’s advisable to confirm material compatibility with SourcifyChina when placing your order.