FAQ for Manufacturing “Vertical Form Fill Seal Machine Quality Work from SourcifyChina Factory”

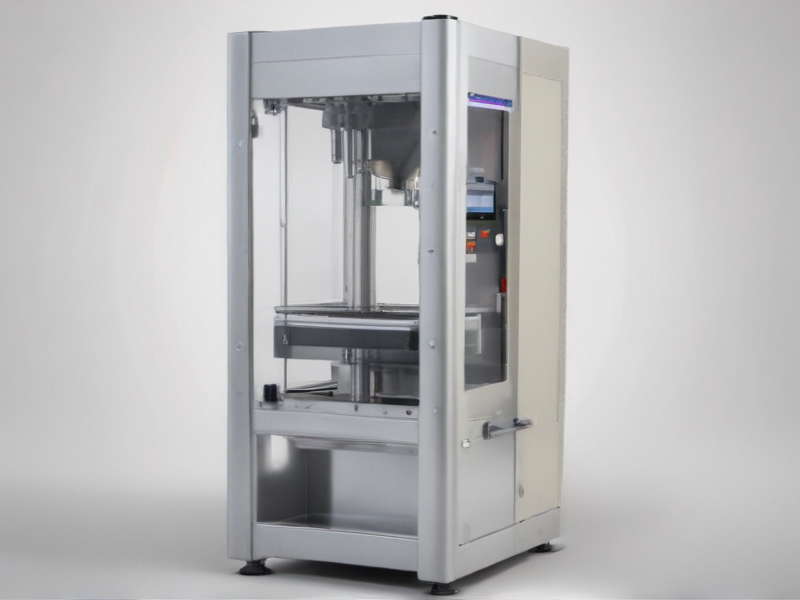

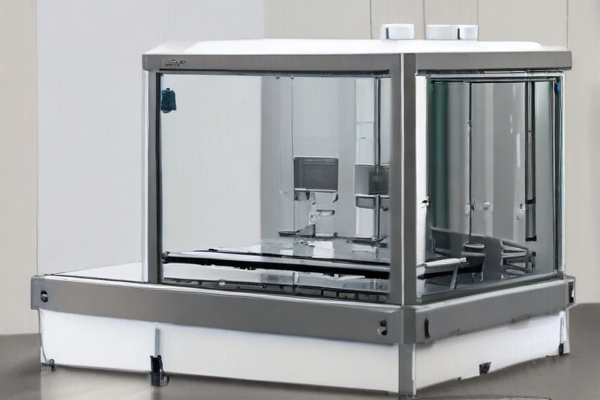

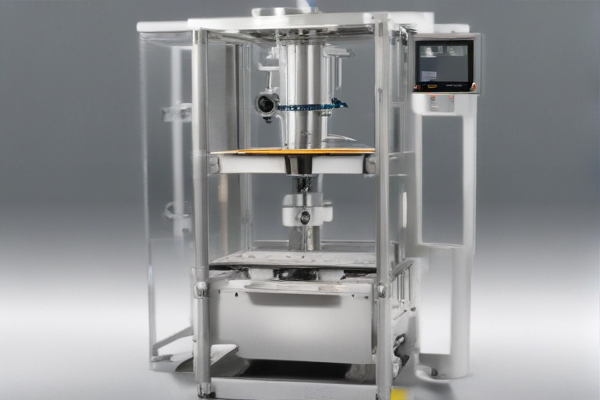

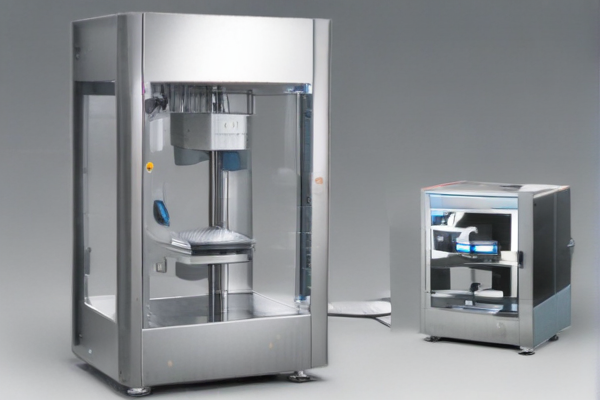

1. What is a Vertical Form Fill Seal (VFFS) machine?

A VFFS machine is a type of packaging equipment that forms, fills, and seals products into pouches or bags in a vertical orientation. It is commonly used for packaging food, pharmaceuticals, and other consumer goods.

2. Why should I choose SourcifyChina for VFFS machines?

SourcifyChina prides itself on high-quality manufacturing standards, advanced technology, and efficient production processes. Our VFFS machines offer reliability, precision, and are designed to meet customized requirements.

3. What materials can the machine handle?

The VFFS machine can handle a wide range of materials, including polyethylene, polypropylene, laminated films, and multi-layer structures.

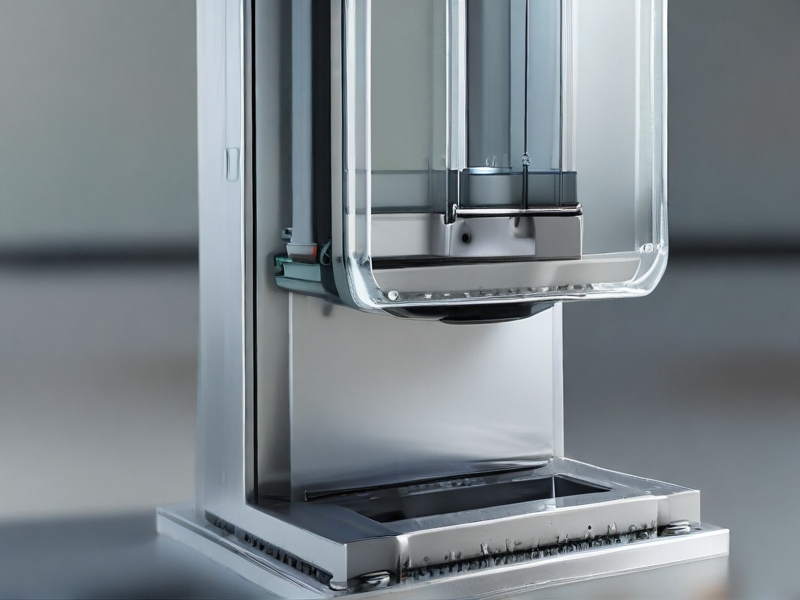

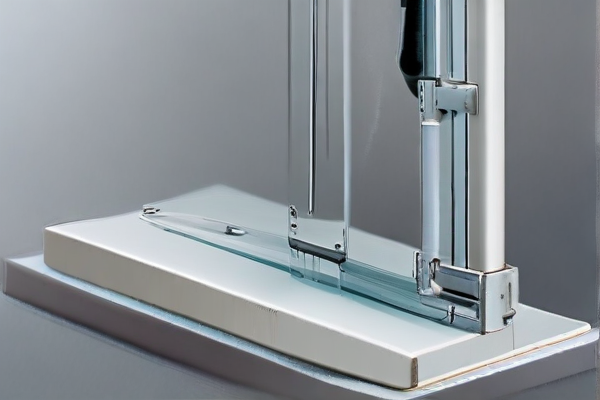

4. What are the key features of SourcifyChina’s VFFS machines?

Our VFFS machines feature high-speed operation, precision sealing, user-friendly interfaces, and robust construction. They are also equipped with advanced control systems for consistent performance.

5. Can your VFFS machines be customized?

Yes, our VFFS machines can be customized to meet specific requirements, such as bag size, type of product, and production speed.

6. How do you ensure the quality of your VFFS machines?

We implement strict quality control measures at every stage of production, from raw material selection to final assembly. Each machine undergoes rigorous testing before delivery.

7. What kind of support and maintenance do you offer?

We offer comprehensive support, including installation assistance, operator training, and ongoing maintenance services to ensure your machine operates efficiently.

8. How long is the lead time for a VFFS machine?

The lead time varies depending on customization and order volume, but generally, it ranges from 4 to 8 weeks.

9. What are the payment terms?

Our standard payment terms include a 30% deposit upfront, with the remaining balance due before shipment. Other terms can be discussed based on the contract.

10. Can I visit your factory?

Yes, we welcome factory visits. Please contact us to schedule an appointment and experience our manufacturing capabilities firsthand.