Sure, here are some frequently asked questions (FAQ) about manufacturing vertical form fill sealing machines with a focus on quality work provided by SourcifyChina factory:

1. What materials are used in the construction of your vertical form fill sealing machines?

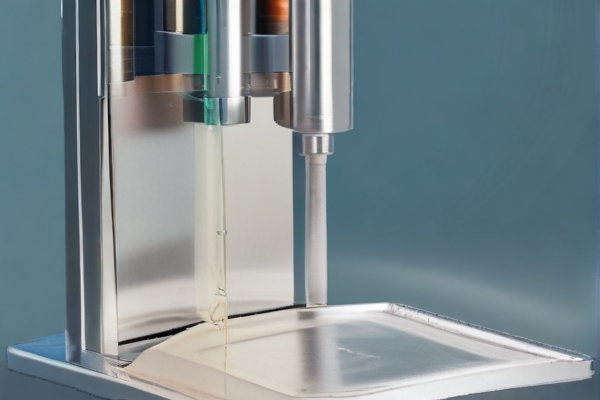

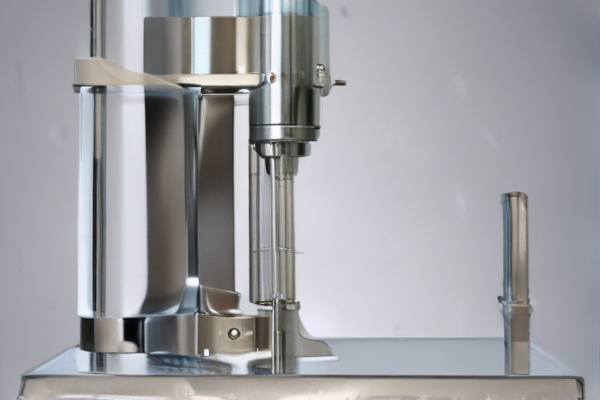

Our vertical form fill sealing machines are made from high-grade stainless steel and other robust materials to ensure durability, hygiene, and long-lasting performance. These materials also meet the highest industry standards for food safety and packaging quality.

2. Do your machines comply with international quality standards?

Yes, our machines are designed and manufactured to comply with international quality standards such as ISO, CE, and FDA regulations. We prioritize quality assurance at every stage of the production process.

3. What kind of products can your vertical form fill sealing machines handle?

Our machines are versatile and can handle a wide range of products including granules, powders, liquids, and solids. They are widely used in industries such as food, pharmaceuticals, chemicals, and cosmetics.

4. What are the lead times for manufacturing and delivery?

Typically, our lead times range from 4 to 8 weeks, depending on the complexity and customization requirements of the project. We strive to deliver within the agreed timeframe without compromising on quality.

5. Can your machines be customized to meet specific requirements?

Absolutely. We offer customized solutions to meet the specific requirements of our clients, including custom sizes, specialized features, and integration with other equipment.

6. What kind of after-sales support do you offer?

We provide comprehensive after-sales support, including installation assistance, training, maintenance services, and prompt troubleshooting. Our support team is available 24/7 to address any technical issues or queries.

7. How do you ensure the quality of your machines?

Quality is our top priority. We implement stringent quality control processes, including multiple testing phases such as functionality tests, material checks, and compliance assessments. Each machine undergoes rigorous inspection before leaving the factory.

8. What are the power requirements for these machines?

Our machines are typically designed to be compatible with standard industrial power requirements. However, we can adjust the specifications as per the power supply standards of your region to ensure seamless operation.

9. How user-friendly are your machines?