Sure, here is a concise FAQ list for manufacturing “vertical packaging machine quality work from SourcifyChina factory”:

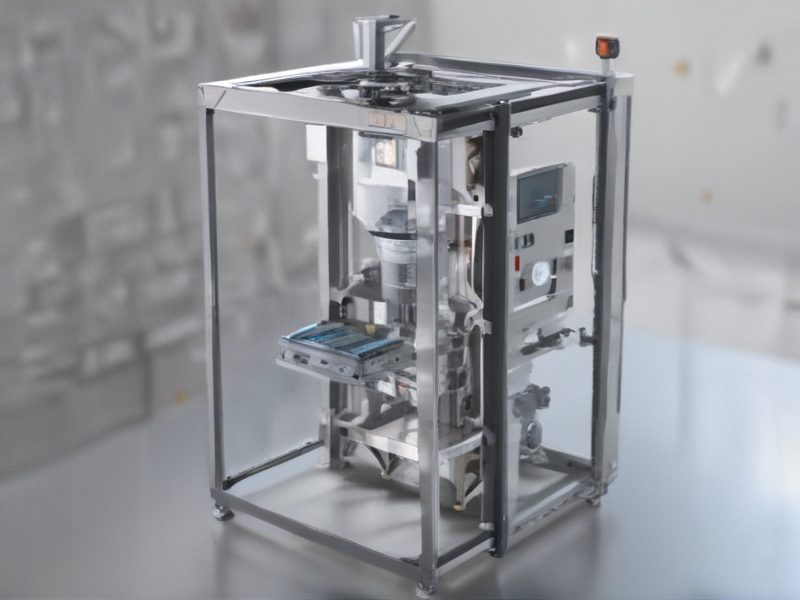

Q1: What types of vertical packaging machines do you manufacture?

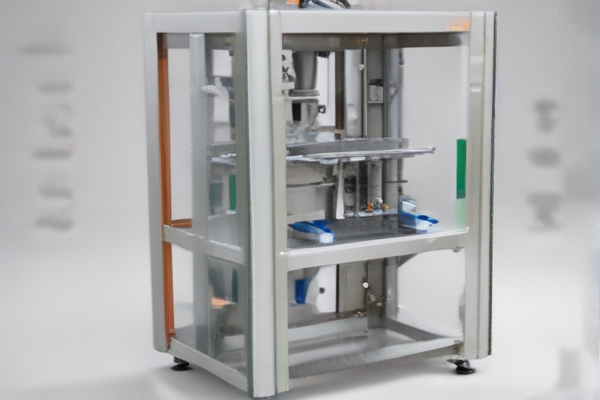

A1: SourcifyChina manufactures a variety of vertical packaging machines, including VFFS (Vertical Form Fill Seal) machines, stick pack machines, sachet packing machines, and auger filling machines. These cater to different industries such as food, pharmaceuticals, and cosmetics.

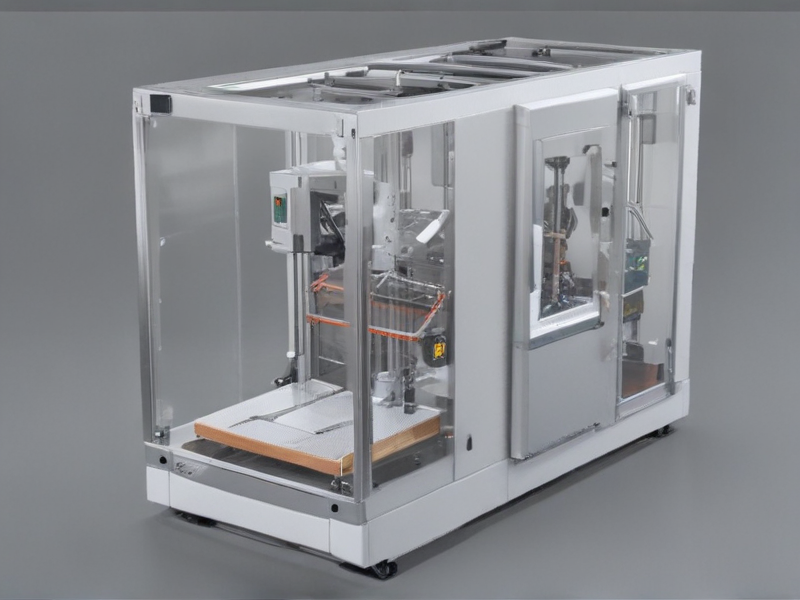

Q2: What materials are used for constructing the machines?

A2: Our machines are constructed using high-quality stainless steel, ensuring durability, hygiene, and compliance with international standards. Specific components are sourced from reputable suppliers to ensure longevity and efficiency.

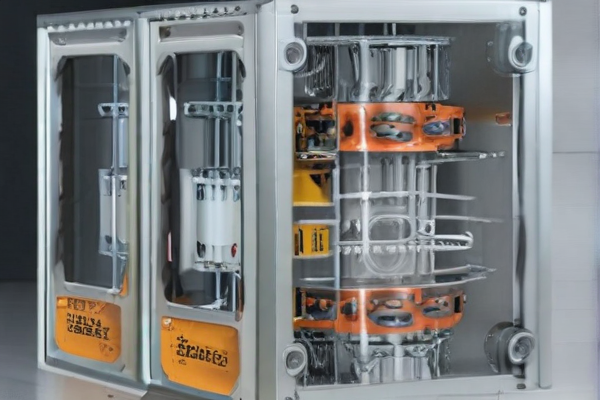

Q3: How do you ensure the quality of your vertical packaging machines?

A3: We have a stringent quality control process that includes rigorous testing at multiple stages of production. Each machine undergoes performance checks, calibration, and validation to ensure it meets the required specifications and operational standards.

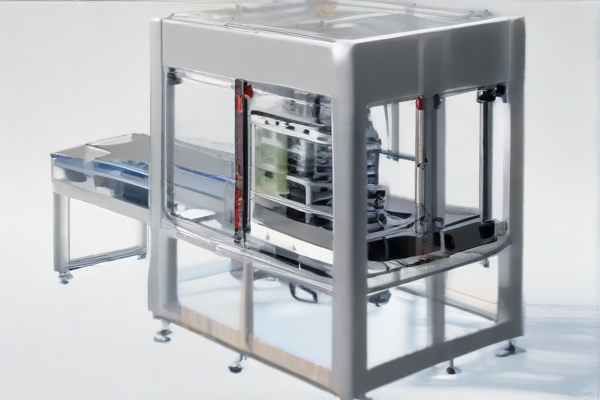

Q4: Can your machines be customized to meet specific needs?

A4: Yes, SourcifyChina offers customization options to meet unique requirements. Our team works closely with customers to design and configure machines that suit their specific packaging needs and production environments.

Q5: What is the lead time for manufacturing and delivery?

A5: The lead time varies depending on the complexity and customization of the machine. Generally, it ranges from 4 to 8 weeks. Detailed timelines are provided after the initial consultation and order confirmation.

Q6: Do you provide after-sales service and support?

A6: Yes, we offer comprehensive after-sales service including installation assistance, training, maintenance, and technical support. Our service team is always available to ensure smooth operation and minimize downtime.

Q7: What is the warranty period for your machines?

A7: SourcifyChina provides a standard one-year warranty on all vertical packaging machines. The warranty covers manufacturing defects and parts replacement. Extended warranty options are also available upon request.

Q8: Are your machines energy-efficient?

A8: Absolutely. Our vertical packaging machines are designed to be energy-efficient and environmentally friendly, using advanced technology to minimize power consumption while maximizing productivity.

This FAQ should provide a clear and concise overview for anyone considering purchasing vertical packaging machines from SourcifyChina factory.