Sure, here is a list of frequently asked questions (FAQs) with answers for sourcing vertical packaging machines from SourcifyChina factory:

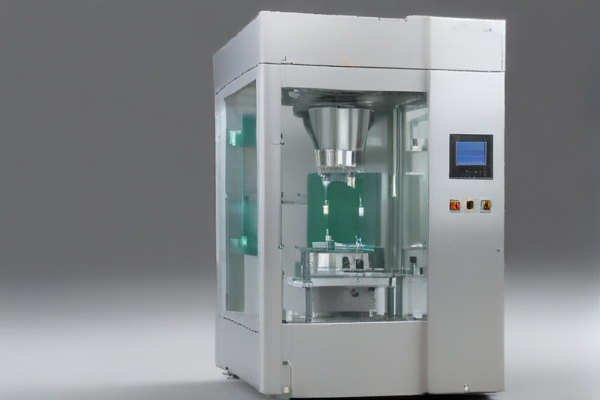

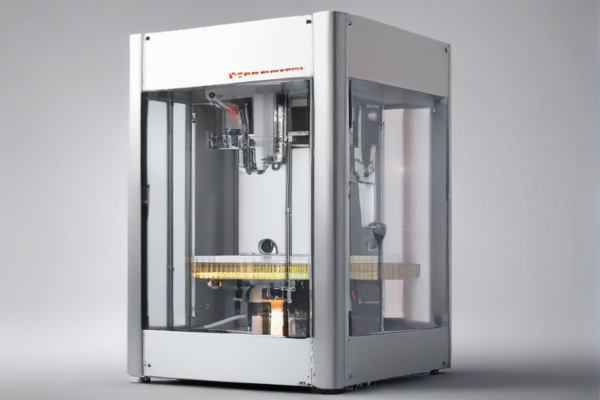

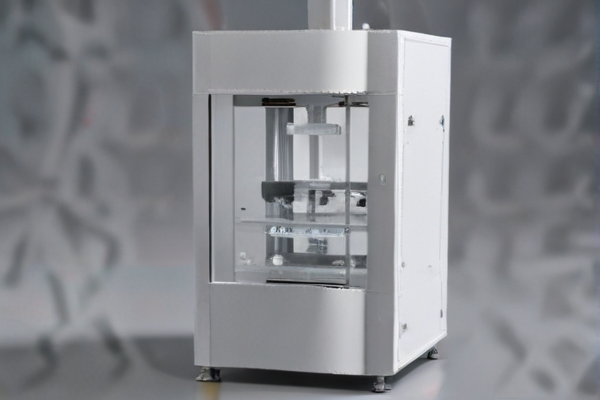

1. What types of vertical packaging machines does SourcifyChina offer?

SourcifyChina provides a range of vertical packaging machines, including form-fill-seal machines, vertical cartoners, and multi-head weighers, suitable for various products such as powders, granules, and liquids.

2. How do I place an order for vertical packaging machines?

To place an order, you can visit the SourcifyChina website, browse the product catalog, and fill out the inquiry form. A sales representative will contact you for further assistance.

3. What is the lead time for delivery?

The lead time for delivery varies based on the machine type and customization requirements. Typically, it ranges from 4 to 8 weeks after the order confirmation.

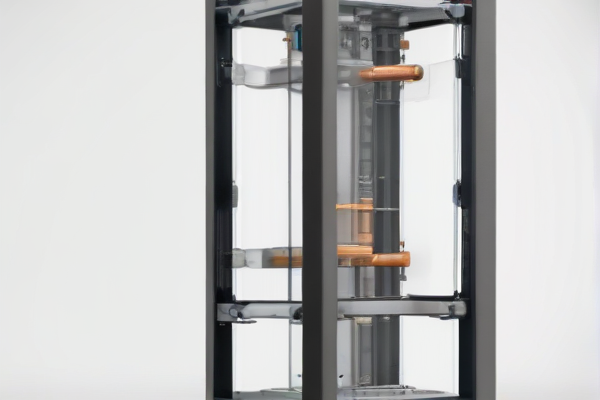

4. Can I customize the vertical packaging machines according to my needs?

Yes, SourcifyChina offers customization services. You can specify machine configurations, material types, and additional features to meet your unique packaging requirements.

5. What kind of technical support and after-sales service does SourcifyChina provide?

SourcifyChina provides comprehensive technical support, including installation, training, and troubleshooting. After-sales service includes maintenance, spare parts supply, and remote assistance.

6. Do the vertical packaging machines come with a warranty?

Yes, SourcifyChina offers a standard one-year warranty on all vertical packaging machines. Extended warranties can be negotiated based on the requirements.

7. Are the machines compliant with international standards?

SourcifyChina’s vertical packaging machines comply with international standards such as CE and ISO, ensuring quality and safety.

8. What are the payment terms?

Payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and other flexible options. Usually, a down payment is required with the balance payable before shipment.

9. Can I visit the factory for a machine demonstration?

Yes, you are welcome to visit the SourcifyChina factory. Appointments can be scheduled through the sales team to arrange a demonstration.

10. How do I get a quotation for the vertical packaging machines?

To get a quotation, contact SourcifyChina through their website, email, or phone. Provide details about your packaging needs, and a customized quote will be prepared for you.

This compact FAQ should cover the primary concerns potential buyers may have when sourcing vertical packaging machines from SourcifyChina factory.