FAQ for Manufacturing VFFS Machine Quality Work from SourcifyChina Factory

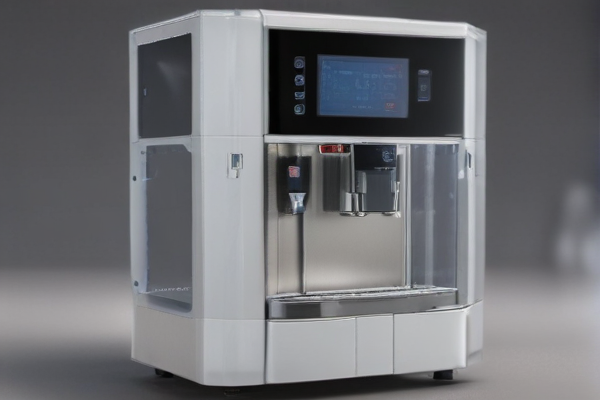

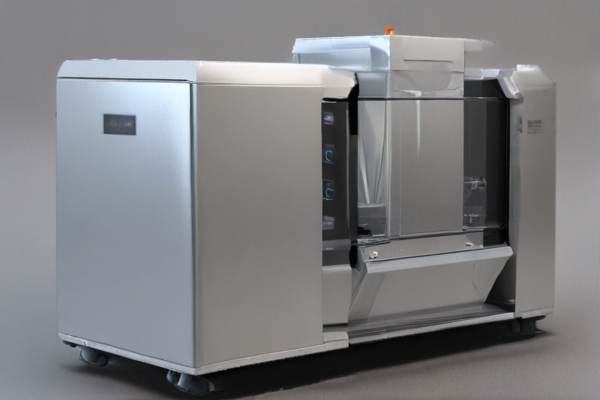

What is VFFS?

Vertical Form Fill Seal (VFFS) is a type of machine used in packaging products into pouches or bags. It forms the packaging material, fills the product, and seals it in a vertical orientation.

Why should I choose SourcifyChina for VFFS machines?

SourcifyChina is known for its high-quality manufacturing standards, advanced technology integration, and exceptional customer support. Our VFFS machines are built to deliver efficient, accurate, and reliable performance.

What types of products can a VFFS machine handle?

Our VFFS machines can handle a wide range of products including granules, powders, liquids, and solids. They are ideal for packaging food items, pharmaceuticals, chemicals, and more.

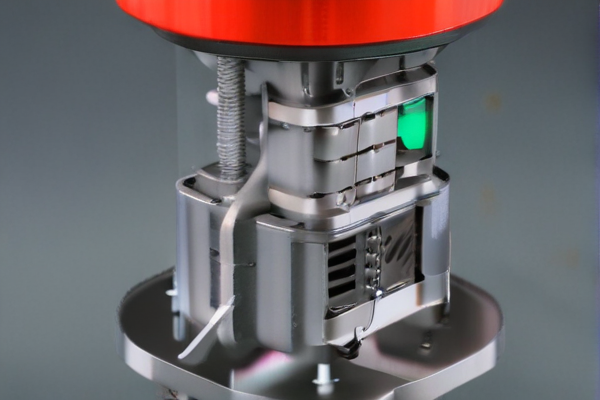

What are the quality standards followed at SourcifyChina?

We adhere to international quality standards such as ISO 9001 and CE certifications. Every machine undergoes rigorous testing and quality checks to ensure it meets our high standards.

Can I customize my VFFS machine?

Yes, SourcifyChina offers customization options to meet specific requirements. You can choose from various models, sizes, and features to best suit your production needs.

What is the lead time for a VFFS machine order?

The lead time typically ranges from 4 to 8 weeks, depending on the complexity and customization requirements of the machine. We strive to deliver within the agreed timeframe.

Do you provide after-sales service?

Absolutely. SourcifyChina offers comprehensive after-sales support, including installation, training, maintenance, and troubleshooting services.

How do I place an order with SourcifyChina?

You can place an order by contacting our sales team through our website or by email. We will guide you through the process, from selecting the right machine to finalizing the order details.

What payment methods do you accept?

We accept various payment methods including wire transfers, letters of credit, and other secure payment gateways. Please consult our sales team for detailed payment terms.

Is there a warranty on the VFFS machines?

Yes, all our VFFS machines come with a standard one-year warranty. Additional warranty and service plans are also available upon request.

This concise FAQ aims to address common queries quickly and effectively, staying well within a 300-word limit.