Frequently Asked Questions about Visual Inspection Equipment Manufacturing at SourcifyChina Factory

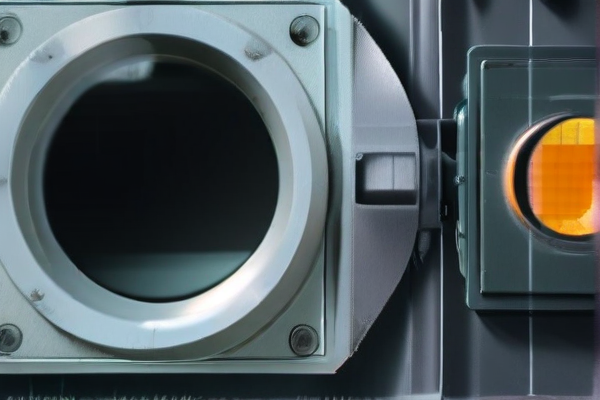

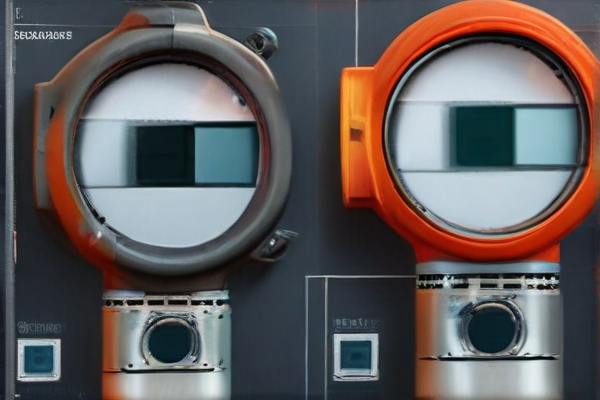

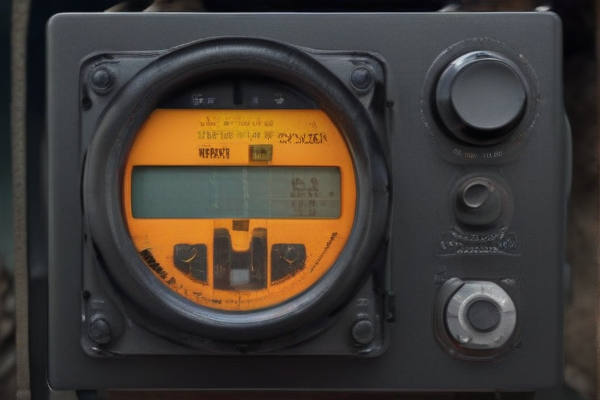

Q: What types of visual inspection equipment do you manufacture?

A: SourcifyChina specializes in various visual inspection equipment, including automated optical inspection (AOI) machines, vision systems for quality control, and custom-made solutions tailored to specific manufacturing needs.

Q: How do I know if visual inspection equipment is suitable for my production line?

A: Our team provides a thorough assessment of your production line requirements. We analyze factors such as production speed, defect types, and inspection accuracy to recommend the most suitable equipment for your needs.

Q: Can the visual inspection equipment be customized?

A: Yes, we offer customization options to tailor the equipment to specific industry requirements, product types, and inspection criteria. This ensures optimal performance and accuracy in your unique manufacturing environment.

Q: What is the lead time for manufacturing visual inspection equipment?

A: The lead time varies depending on the complexity of the equipment and customization requirements. Standard equipment typically takes 4-6 weeks, while customized solutions might require 8-12 weeks.

Q: How do you ensure the quality of the visual inspection equipment?

A: SourcifyChina employs rigorous quality control processes, including multiple stages of testing and validation, to ensure that each piece of equipment meets international quality standards and performs reliably in demanding industrial conditions.

Q: What kind of after-sales support do you provide?

A: We offer comprehensive after-sales support, including installation assistance, training for your staff, regular maintenance services, and a responsive technical support team to address any issues promptly.

Q: Are there any industry certifications for your equipment?

A: Our visual inspection equipment complies with international standards and certifications, such as ISO 9001, CE, and RoHS, ensuring high quality and safety.

Q: How can I place an order for visual inspection equipment?

A: You can contact us directly through our website, email, or phone. Our sales team will guide you through the ordering process, providing detailed information and assistance with your specific requirements.

Q: Do you provide training for the operation of the visual inspection equipment?

A: Yes, we offer comprehensive training programs to ensure that your team can operate and maintain the equipment effectively, enhancing productivity and efficiency in your manufacturing process.