Sure! Here’s a short FAQ for sourcing water bottling machines from the SourcifyChina factory:

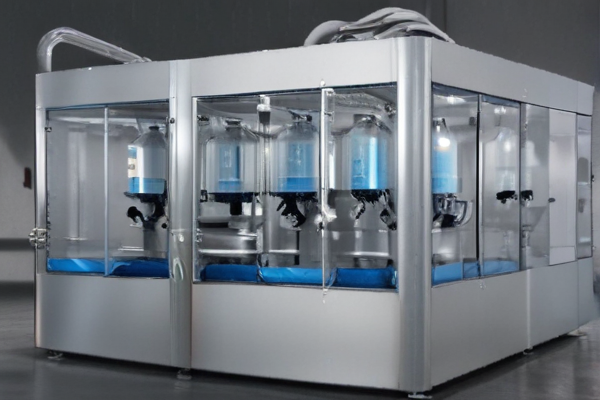

1. What types of water bottling machines does SourcifyChina offer?

SourcifyChina offers a range of water bottling machines, including automatic, semi-automatic, and manual machines. These machines can handle different bottle sizes and types, such as PET, glass, and aluminum.

2. How can I get a quote for a water bottling machine?

To get a quote, you can visit SourcifyChina’s official website and fill out the contact form with your specific needs and requirements. You can also email their sales team directly with your project details.

3. What is the lead time for delivery?

The lead time for delivery typically ranges from 4 to 12 weeks, depending on the complexity of the machine and current production schedules. It’s best to confirm with the factory at the time of order.

4. Do you offer customization options?

Yes, SourcifyChina provides customization options to meet unique client requirements. This includes modifications in machine capacity, layout, and additional features like labeling and packaging.

5. Is there a minimum order quantity (MOQ)?

The minimum order quantity can vary depending on the specific machine and customization needed. It’s advisable to contact SourcifyChina directly to discuss your project’s MOQ.

6. What support and maintenance services are available?

SourcifyChina offers comprehensive support, including installation, training, and maintenance services. They also provide spare parts and remote troubleshooting assistance.

7. How do you ensure the quality of the machines?

SourcifyChina adheres to strict quality control measures, including rigorous testing of machines before delivery. They also have certifications and quality standards such as ISO and CE.

8. What are the payment terms?

Payment terms typically include a deposit of 30% upon order confirmation, with the remaining 70% due before shipment. It’s essential to confirm the terms during the negotiation process.

9. Are the machines energy-efficient?

Yes, SourcifyChina’s water bottling machines are designed to be energy-efficient, helping clients reduce operational costs and environmental footprint.

10. How do I arrange shipment and logistics?

SourcifyChina can assist with shipment and logistics arrangements. They offer various shipping options like FOB, CIF, and DDP, depending on the client’s preference.