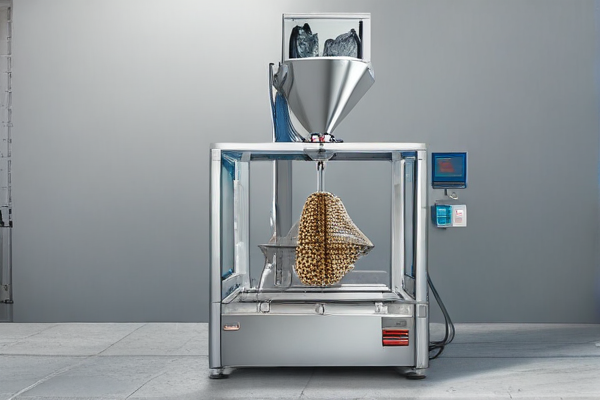

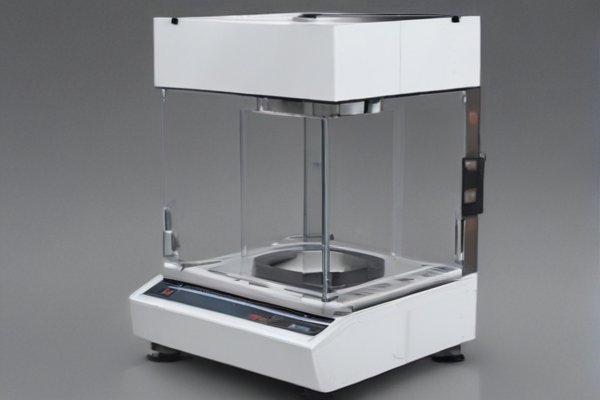

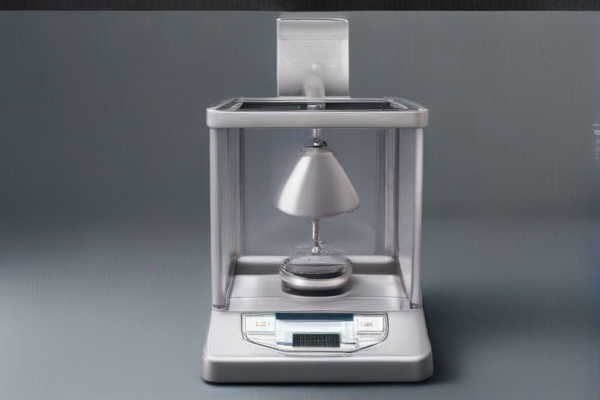

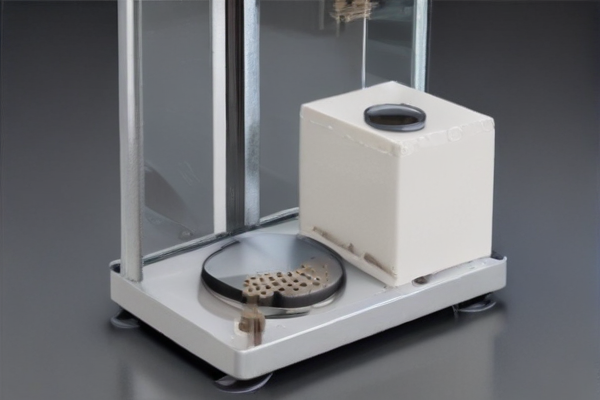

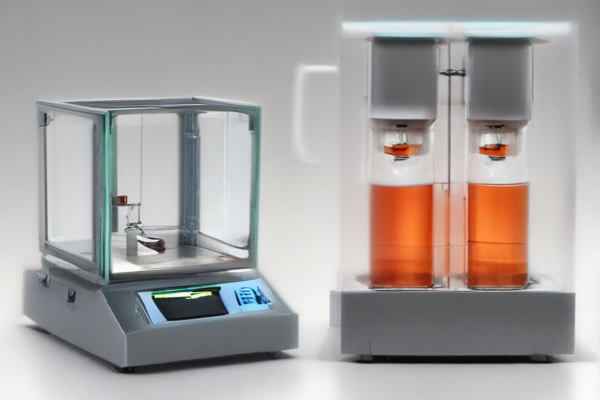

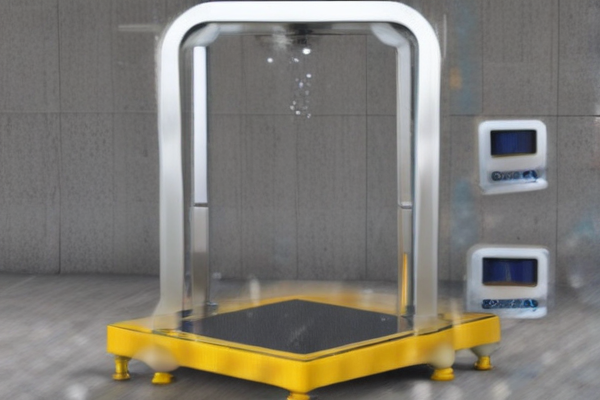

When sourcing a weighing and filling machine from SourcifyChina factory, follow these tips to ensure a smooth and efficient procurement process:

1. Define Your Requirements:

– Determine your specific needs, including machine capacity, accuracy, speed, and any special features required for your products.

2. Research the Supplier:

– Visit SourcifyChina’s website and explore their product catalog.

– Read customer reviews and testimonials to gauge reliability and service quality.

3. Request Quotes:

– Contact SourcifyChina directly to request a detailed quote.

– Compare prices with other suppliers to ensure competitive pricing.

4. Clarify Specifications:

– Ensure all technical specifications of the weighing and filling machine match your requirements.

– Ask for product manuals or datasheets for a deeper understanding.

5. Check Certifications:

– Verify that the machines comply with relevant industry standards and certifications (e.g., ISO, CE).

6. Discuss Customization:

– Inquire about the possibility of customizing the machine to better fit your production line.

7. Evaluate After-Sales Support:

– Assess the availability of technical support and spare parts.

– Confirm warranty terms and conditions.

8. Request Samples or Demonstrations:

– If possible, ask for a sample or arrange a live demonstration to witness the machine in action.

9. Negotiate Terms:

– Discuss payment terms, delivery schedules, and Incoterms (e.g., FOB, CIF).

– Secure favorable terms to minimize financial risk.

10. Inspect and Test Before Shipment:

– Arrange for a third-party inspection or factory visit to ensure the machine meets quality standards.

– Test the machine for operational efficiency before finalizing the purchase.

By diligently following these steps, you can ensure a successful acquisition of a weighing and filling machine from SourcifyChina that meets your operational needs and quality expectations.