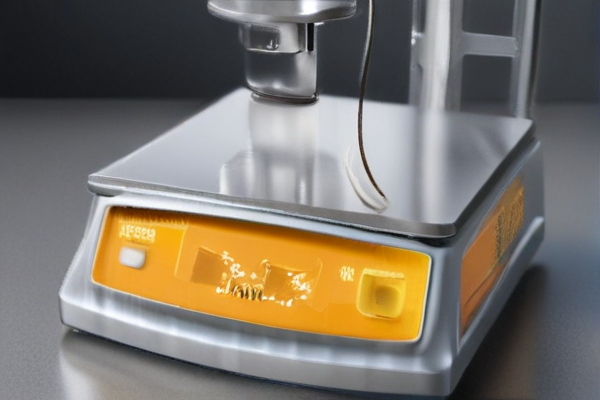

Sourcing a weighing filling machine from a factory like SourcifyChina can be a streamlined process with the right approach. Here are some tips to help you source effectively:

1. Research and Identify Needs:

– Determine your specific requirements such as machine capacity, accuracy, and the type of materials it will handle.

– Prepare a detailed specification sheet.

2. Verify Factory Credentials:

– Check whether SourcifyChina is a verified supplier. Look for certifications, industry standards, and reviews from previous clients.

– Request documentation proving their compliance with international quality standards.

3. Request Quotations:

– Contact SourcifyChina directly through their official communication channels.

– Provide your detailed specifications to get an accurate quote.

4. Evaluate Quotes and Lead Time:

– Compare prices and lead times. Consider total cost, including shipping and potential customs fees.

– Ask about bulk order discounts if applicable.

5. Assess Quality Assurance:

– Inquire about their quality control processes.

– Request to see product sample test reports.

6. Factory Visit or Virtual Tour:

– If feasible, arrange for an in-person visit to the factory.

– Alternatively, request a virtual tour or video demonstration of the production facilities and machine operation.

7. Negotiate Terms:

– Discuss payment terms and conditions, warranty, and after-sales service.

– Ensure there are clear guarantees and support for installation and maintenance.

8. Review Contract Thoroughly:

– Make sure all terms are spelled out in a written contract.

– Look for agreements on delivery schedules and penalties for delays.

9. Pilot Testing:

– If possible, run a small batch test to evaluate machine performance before committing to a full order.

10. Logistics Arrangement:

– Collaborate on shipping logistics, ensuring all necessary paperwork is in place.

– Clarify who handles different segments of the logistics to avoid confusion or delays.

By following these steps, you can minimize risks and ensure a smooth sourcing experience for your weighing filling machine from SourcifyChina.