FAQ: Quality of Wrap Around Labeling Machine from SourcifyChina Factory

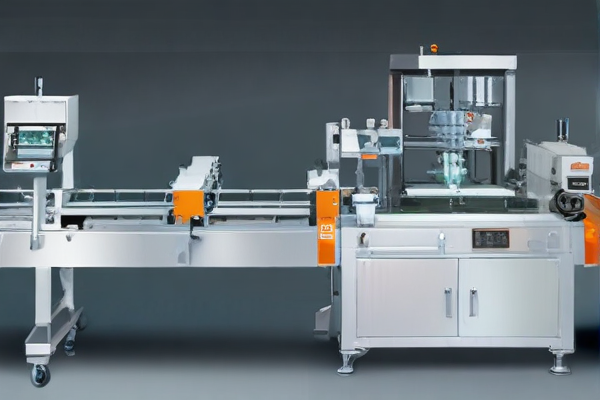

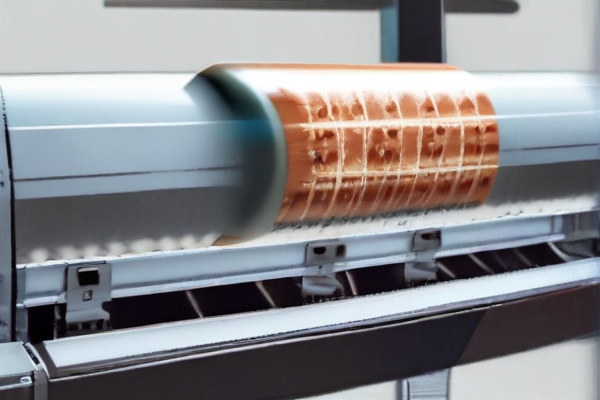

1. What is a wrap-around labeling machine?

A wrap-around labeling machine is designed to apply labels to cylindrical products, such as bottles and cans, by wrapping the label around the product’s circumference.

2. How does SourcifyChina ensure the quality of their labeling machines?

SourcifyChina follows stringent quality control protocols, including thorough inspections at each manufacturing stage, using high-quality materials, and adhering to international standards and certifications to ensure top-notch reliability and performance.

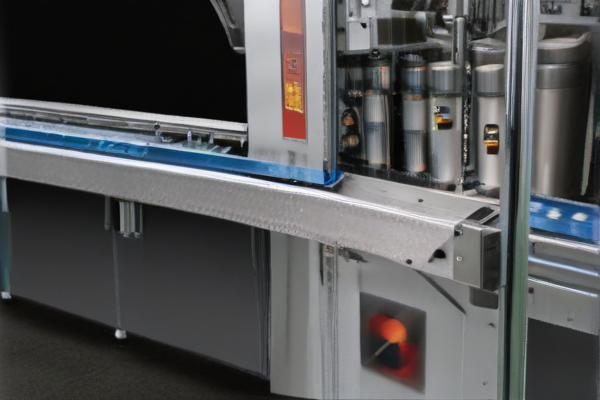

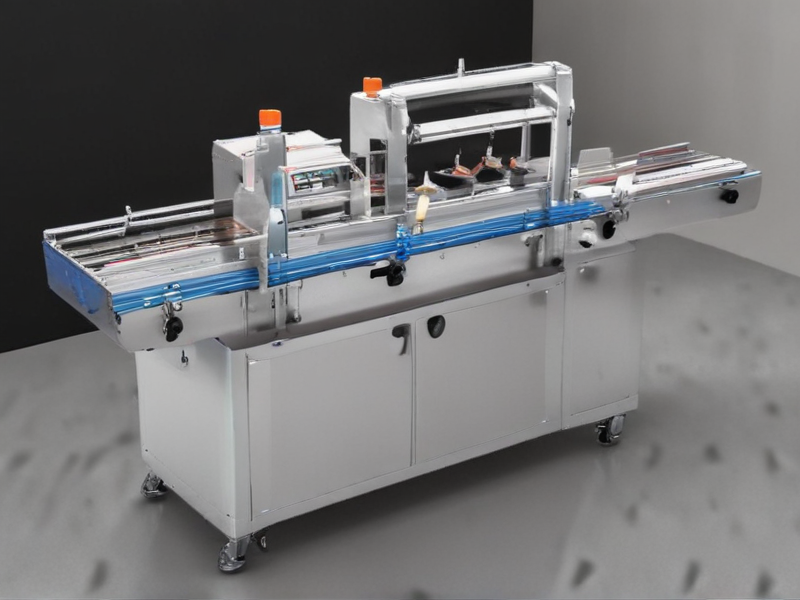

3. What materials are used in the construction of the machines?

The machines are typically made from durable stainless steel and high-grade aluminum, ensuring robustness, corrosion resistance, and longevity even under continuous operation.

4. Are the machines from SourcifyChina customizable?

Yes, SourcifyChina offers customizable options to meet specific customer needs, including variable speeds, label sizes, and accommodating different product diameters.

5. What kind of maintenance is required for these labeling machines?

Regular maintenance involves routine checks and cleaning of the labeling heads, belt adjustments, and lubrication of moving parts to ensure smooth operation and prevent wear and tear.

6. How does SourcifyChina support customers post-purchase?

SourcifyChina provides comprehensive after-sales support including technical assistance, troubleshooting, spare parts supply, and training for operators to ensure seamless machine operation.

7. What is the turnaround time for manufacturing and delivery?

The turnaround time may vary based on customization and order size, but typically, manufacturing and delivery can be expected within 4-8 weeks.

8. Can I visit the SourcifyChina factory for an inspection?

Yes, potential customers are welcome to visit the SourcifyChina factory to inspect the manufacturing process and discuss their specific requirements in detail.

9. Are there any warranty options available?

Most machines come with a standard warranty that typically covers one year of service and parts, with options for extended warranties available based on customer needs.

10. How can I place an order or request a quote?

Orders and quote requests can be made directly through SourcifyChina’s official website or by contacting their sales team via email or phone.