Sure, here are some frequently asked questions (FAQ) along with their answers regarding the manufacturing of wrapping machines with quality work from SourcifyChina factory:

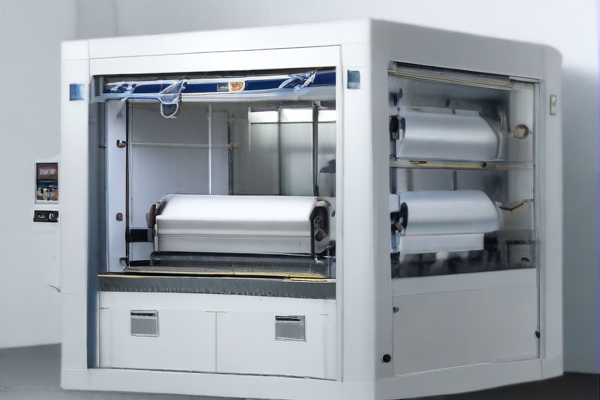

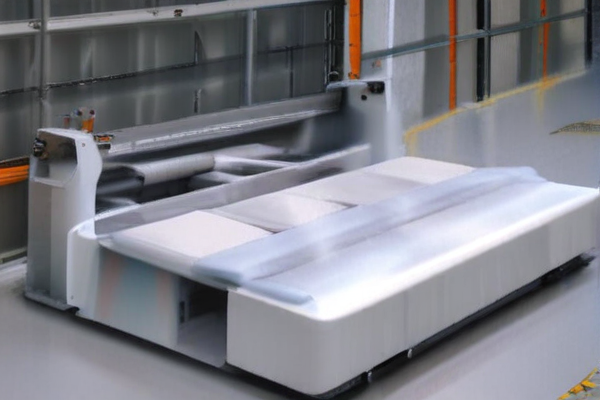

1. What types of wrapping machines does SourcifyChina manufacture?

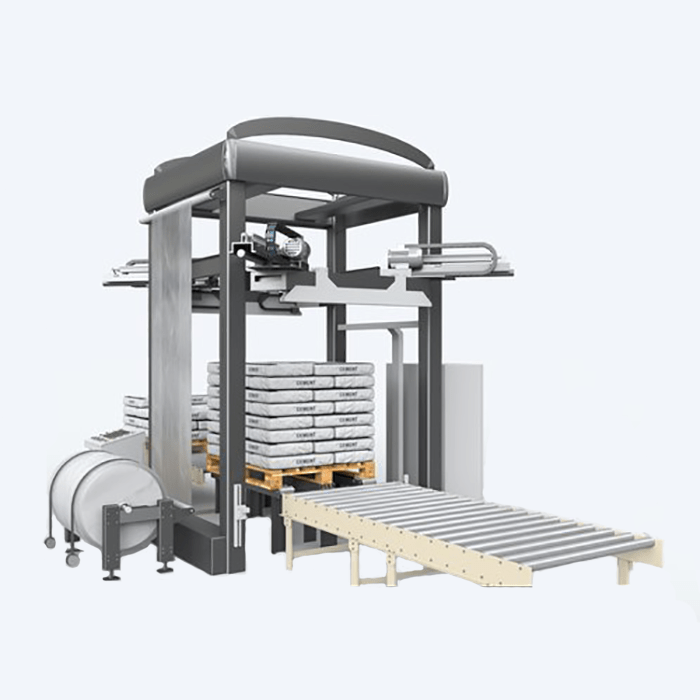

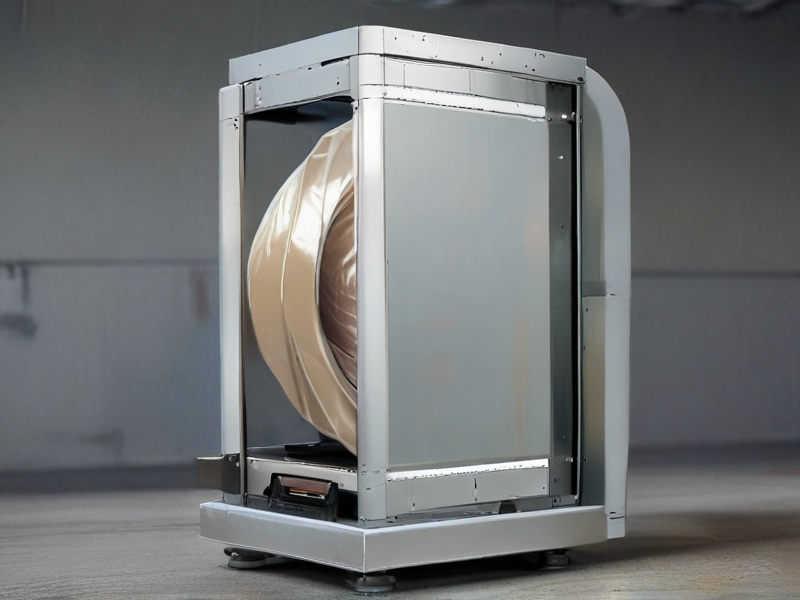

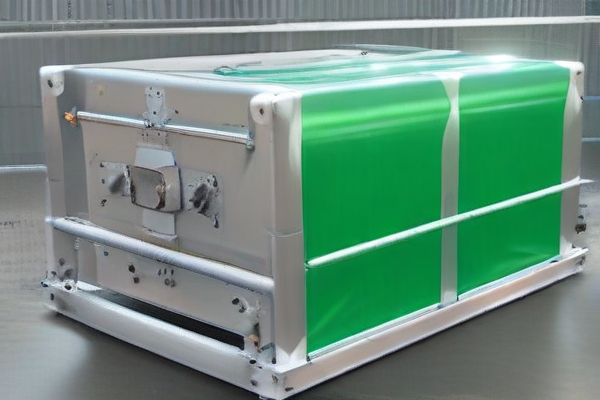

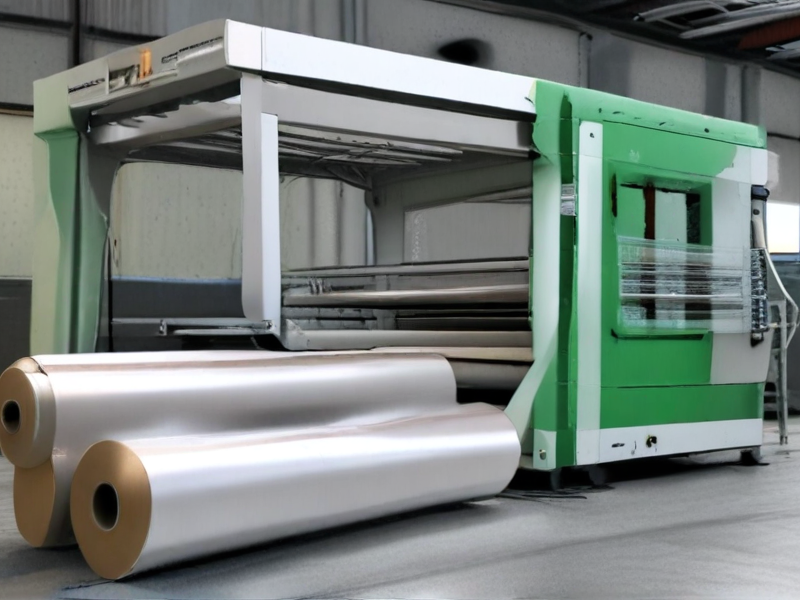

SourcifyChina manufactures a wide range of wrapping machines including automatic, semi-automatic, and manual models for various applications such as pallet wrapping, shrink wrapping, stretch wrapping, and more.

2. How does SourcifyChina ensure the quality of its wrapping machines?

Quality is ensured through rigorous testing, the use of high-quality materials and components, adherence to international manufacturing standards, and continuous quality control processes throughout the production cycle.

3. Can SourcifyChina customize wrapping machines according to specific needs?

Yes, SourcifyChina offers customization services to tailor wrapping machines to meet specific customer requirements regarding size, functionality, and additional features.

4. What is the lead time for manufacturing and delivering a wrapping machine?

The lead time typically ranges from 4 to 8 weeks, depending on the level of customization and order volume. SourcifyChina strives to meet customer deadlines while maintaining quality standards.

5. Does SourcifyChina provide after-sales support and maintenance services?

Yes, SourcifyChina offers comprehensive after-sales support, including maintenance services, spare parts supply, and technical assistance to ensure the long-term performance of their machines.

6. How does SourcifyChina handle international shipping and logistics?

SourcifyChina has an experienced logistics team that handles all aspects of international shipping, ensuring timely and safe delivery of machines to customers worldwide.

7. Are SourcifyChina’s wrapping machines energy-efficient and eco-friendly?

Yes, SourcifyChina places a strong emphasis on sustainability. Their wrapping machines are designed to be energy-efficient and incorporate eco-friendly materials and processes where possible.

8. What kind of training does SourcifyChina provide for operating their wrapping machines?

SourcifyChina provides comprehensive training programs for operators, which include detailed user manuals, video tutorials, and on-site training when required.

9. How can I place an order with SourcifyChina?

You can place an order by contacting SourcifyChina directly through their website, email, or customer service hotline. Their sales team will guide you through the order process.

10. What payment methods are accepted by SourcifyChina?