Sure, here is a concise FAQ for manufacturing “wrapping machinery quality work from SourcifyChina factory”:

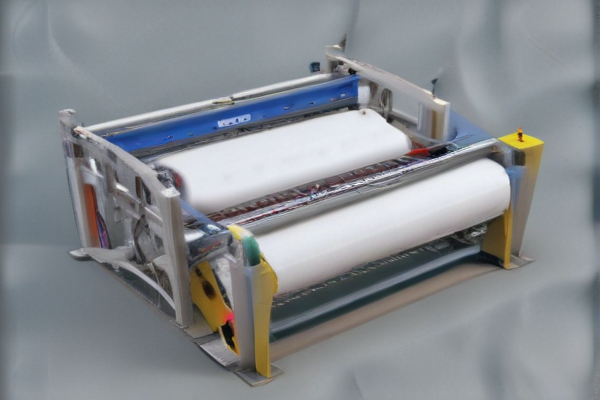

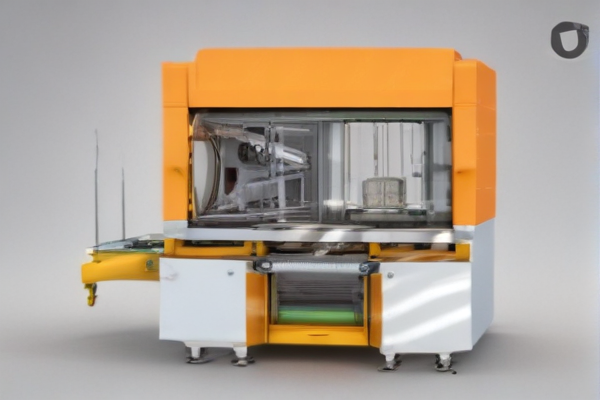

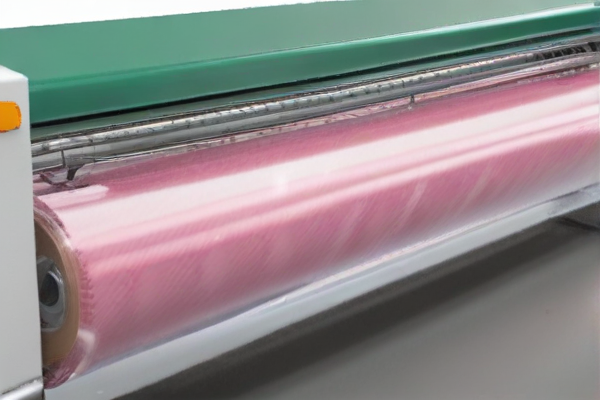

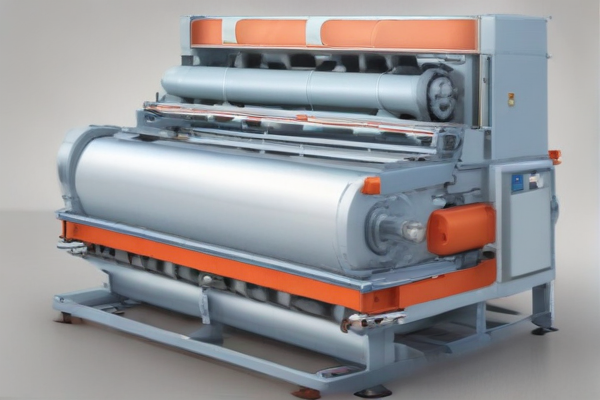

Q1: What types of wrapping machinery does SourcifyChina factory manufacture?

A1: SourcifyChina factory specializes in various types of wrapping machinery, including automatic wrapping machines, semi-automatic wrapping machines, stretch wrappers, pallet wrappers, and shrink wrapping machines.

Q2: What quality standards does the wrapping machinery from SourcifyChina factory adhere to?

A2: Our machinery complies with international quality standards such as ISO 9001 and CE certifications, ensuring high performance, durability, and safety.

Q3: Can SourcifyChina factory customize wrapping machines according to specific requirements?

A3: Yes, we offer customized solutions tailored to meet the unique requirements of our clients, including size, capacity, and specific features.

Q4: What is the lead time for manufacturing and delivery?

A4: The lead time typically ranges from 4 to 8 weeks, depending on the complexity and customization needs of the order.

Q5: Do you provide after-sales support and maintenance services?

A5: Yes, we offer comprehensive after-sales support, including installation guidance, technical training, and maintenance services to ensure optimal performance of our wrapping machinery.

Q6: How can I verify the quality of the wrapping machinery before purchasing?

A6: We invite potential customers to visit our factory for an inspection. Additionally, we provide detailed product specifications, performance reports, and customer references upon request.

Q7: What are the payment terms for purchasing wrapping machinery from SourcifyChina factory?

A7: Our standard payment terms are 30% deposit upon order confirmation and 70% balance before shipment. We also offer flexible payment options to suit our clients’ needs.

Q8: Do you offer global shipping for the wrapping machinery?

A8: Yes, we provide global shipping services and work with reliable logistics partners to ensure timely and safe delivery of our products.

Q9: Is there a warranty on the wrapping machinery?

A9: All our wrapping machinery comes with a 1-year warranty covering parts and labor. Extended warranty options are also available.

Q10: How do I get a quote for wrapping machinery from SourcifyChina factory?

A10: You can contact us through our website, email, or phone to request a quote. Please provide detailed information about your requirements to help us provide an accurate estimate.